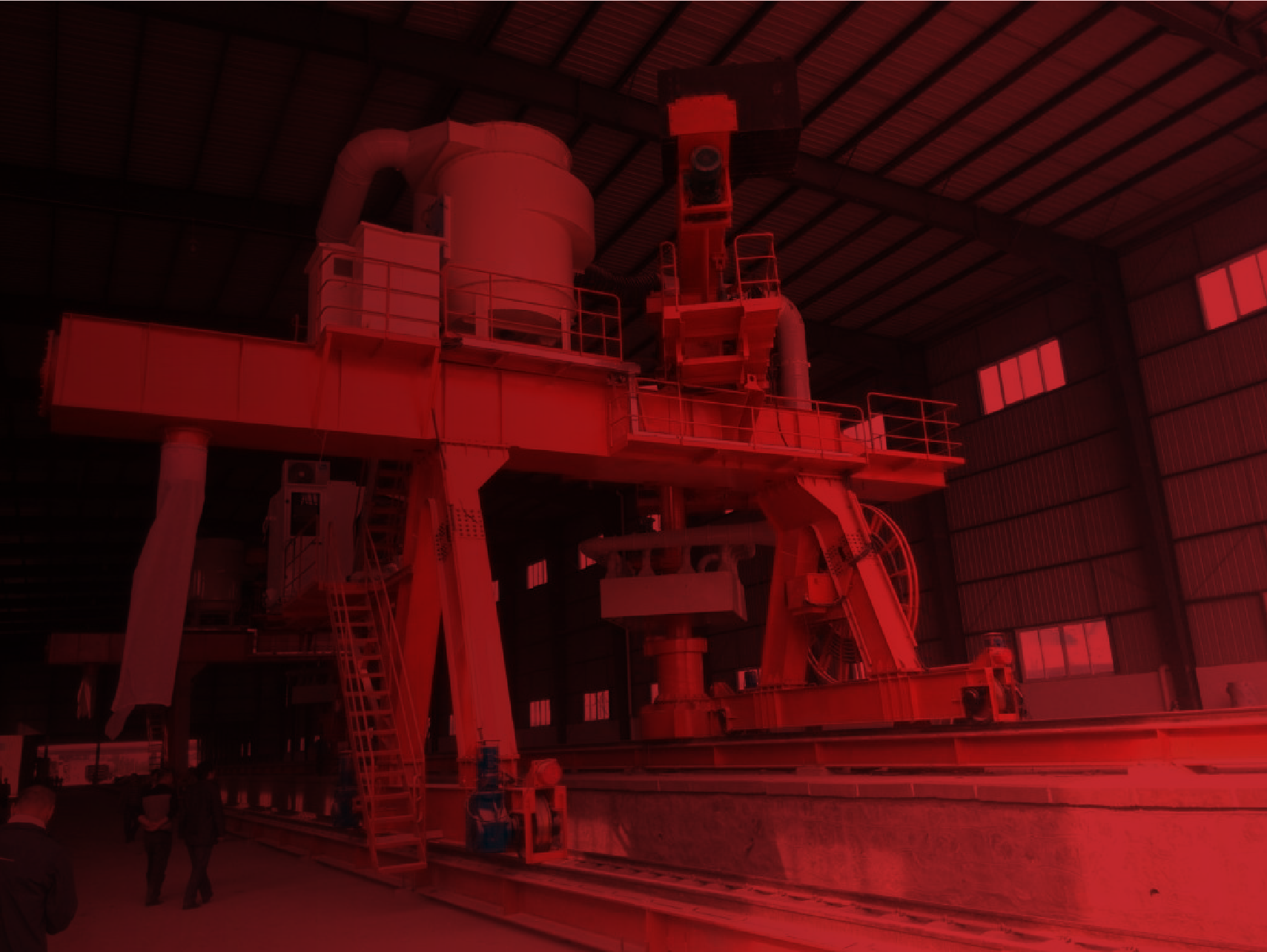

The Cutting-Edge Enclosed Vertical Spiral Machine

The Closed Vertical Spiral Unloading Machine is an advanced, high-tech piece of equipment designed for the efficient unloading of bulk materials such as coal, grain, chemical fertilizers, gasohol derived from cassava, mineral powder and cement. Developed through decades of research and holding multiple national patents, this machine ensures high performance, safety, and environmental protection.

Key Features

- Efficiency

- Environmental Protection

- Energy Saving

- Versatility

- Robust Construction

- Safety

Maintenance

Regular maintenance ensures the longevity and optimal performance of the unloading machine. Key maintenance points include lubrication of motor bearings, checking and tightening of connections, and periodic inspection and replacement of parts as needed.